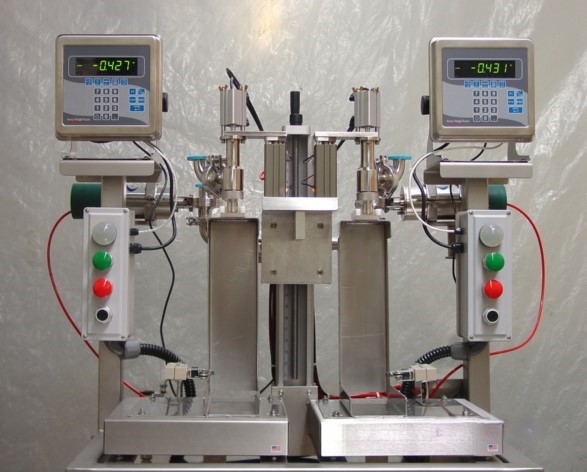

Net Weight Filler Simple Overview

A net weight filler controls the fill by measuring weight, not time or volume. Each jug is isolated on its own scale, verified in position,

Discover the benefits, accuracy, and efficiency of net-weight filling machines in our informative guide.

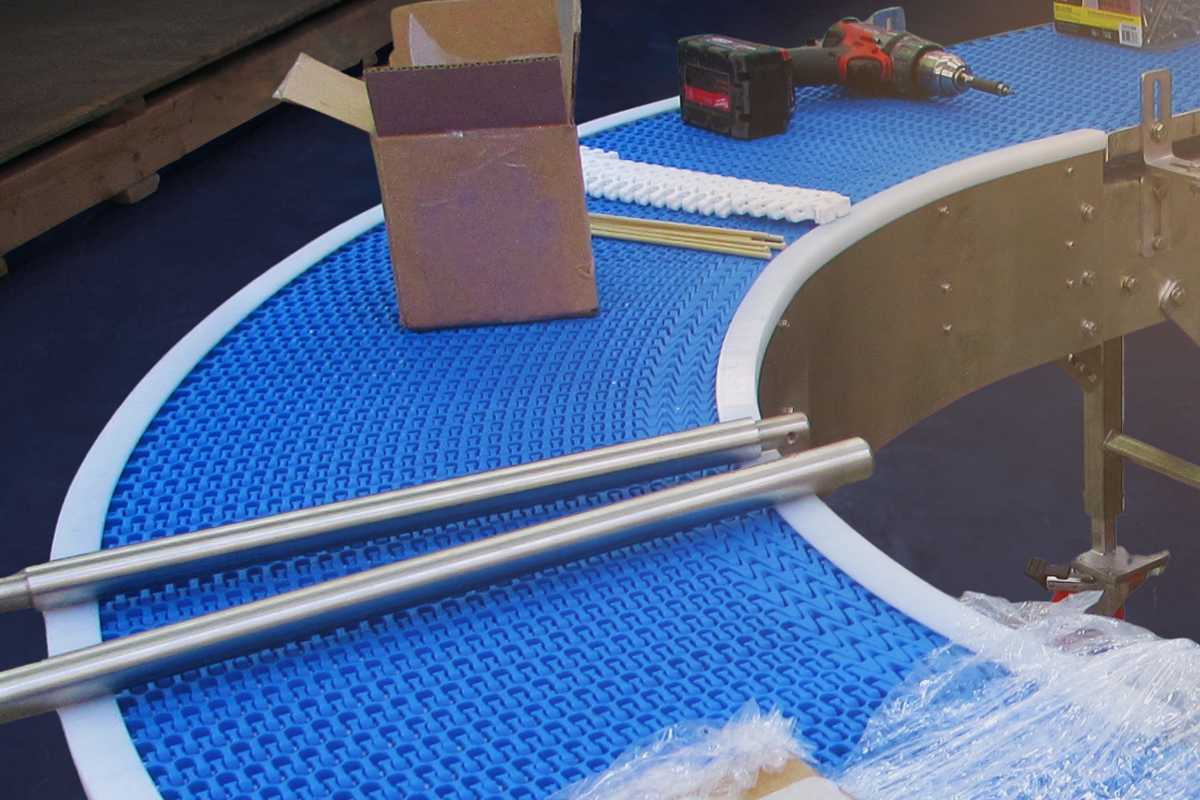

Discover how D&R Packaging offers both custom and standard conveyors solutions to enhance your production line’s efficiency and productivity.

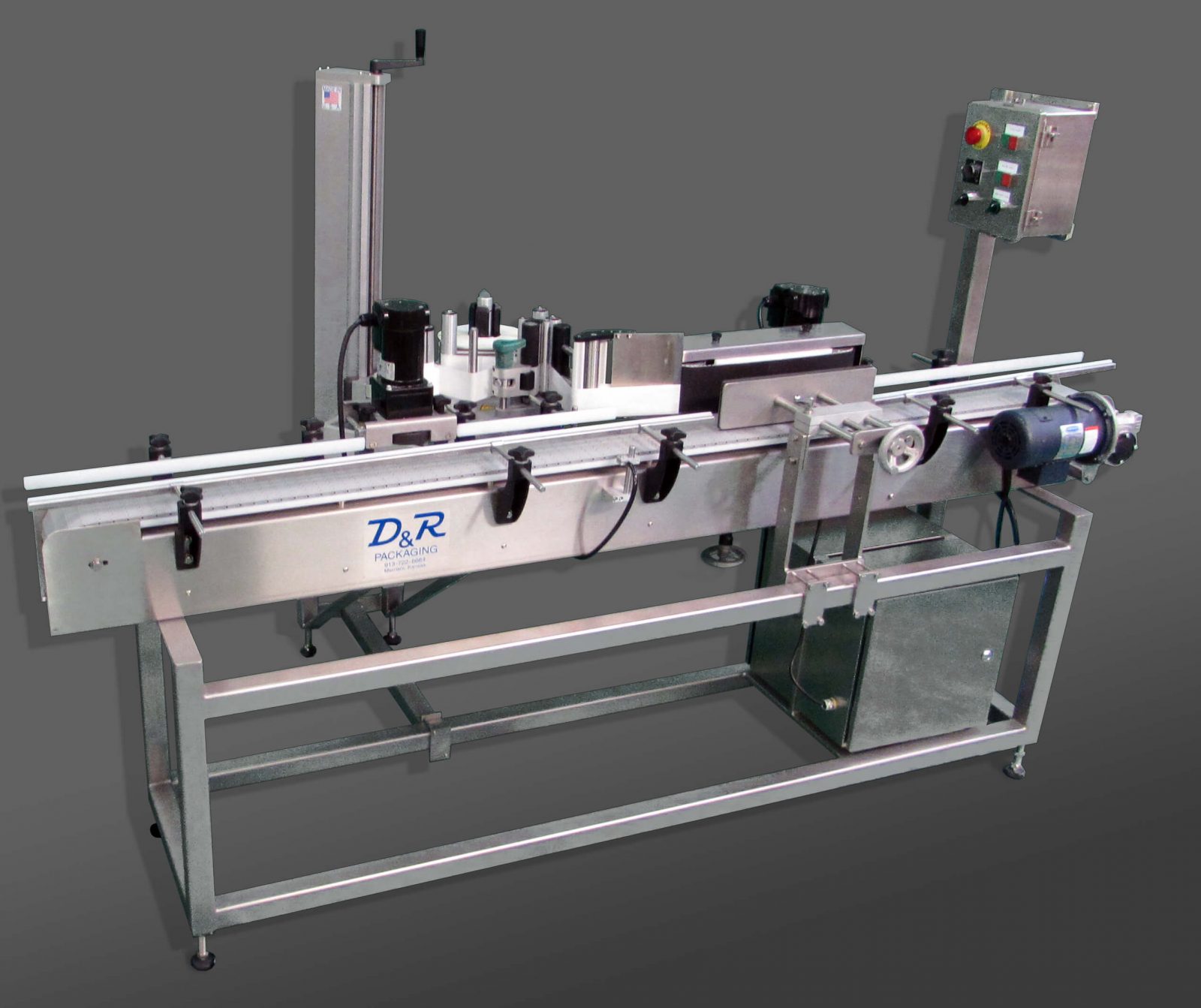

Crucial for consistent product presentation. Discover how D&R Packaging excels in providing top-notch labeling solutions.

Choosing the wrong packaging machinery can impact crucial business operations, and lead to significant issues with production efficiency and integrity of saleable goods. Delays in response times for maintenance support from OEMs and inefficiencies caused by complicated machine setup and operation are common problems within the industry. When urgent production needs go unmet, operational delays result in unnecessary downtime and loss of revenue.

These recurring issues can significantly decrease employee satisfaction as they struggle with inefficient processes, and customer satisfaction due to short orders or inferior product. Lack of reliability and poor performance in packaging machinery can push businesses to the brink. Decision-makers seek reliable automated solutions to restore and maintain efficiency and productivity in the workplace.

Choosing the wrong packaging machinery can lead to significant issues, impacting crucial business operations such as production efficiency and product accuracy, which are essential for day-to-day activities. Delays in response times for maintenance and inefficiencies in machine operation are common problems, where urgent production needs go unmet, causing operational delays and considerable frustration.

These recurring issues can significantly decrease employee satisfaction as they struggle with inefficient processes. The lack of reliability and poor performance from some machines can push businesses to the brink, forcing decision-makers to seek change to restore efficiency and productivity in the workplace.

D&R Packaging stands out as a reliable provider of net weight filling machinery, capable of addressing common issues efficiently. With a focus on reducing downtime and increasing fill accuracy, D&R Packaging ensures that production operations run smoothly, minimizing disruption and maximizing productivity.

Our team is trained to provide professional and courteous service, ensuring that interactions are positive and solutions are delivered swiftly. This level of service not only solves immediate technical problems but also builds a foundation of trust and reliability with our clients.

Since 1986, D&R Packaging has spearheaded innovation and set standards of excellence in the packaging industry. Over the years, our leadership has consistently embraced a forward-thinking approach, staying ahead of emerging trends and technological advancements to effectively serve a diverse clientele across North America.

D&R Packaging stands out by offering a comprehensive suite of packaging equipment designed to operate seamlessly in various production environments. Our innovative approach includes a dedicated support team model, ensuring clients receive personalized and consistent service.

Being a family-owned and operated business, we provide direct access to the owners, who are personally involved with each project. This hands-on involvement ensures meticulous attention to detail and a deep commitment to customer satisfaction. Our background in manufacturing, maintenance, and engineering allows us to understand the critical importance of investing in reliable, high-quality equipment that delivers long-term value and supports future growth.

With years of experience in handling complex projects, D&R Packaging excels at simplifying the process for our customers. We prioritize gathering all relevant information at the start of the project to fully understand your production requirements. Our collaborative approach allows us to either work alongside you or take full control of the project, ensuring it meets your expectations. By addressing the inherent risks in a production environment—whether related to operator safety, maintenance ease, or production rates—right from the start, we ensure a smoother and safer transition when the finished product arrives at your facility.

"EGE Products is an Ag Chemical manufacturing company, and D&R Packaging has been an integral part of our success.

Working with D&R Packaging on our Dual Automated packaging lines is simple and cost effective with their full service program including design, installation, and on-going support.

The customer service at D&R Packaging is top tier. They are available whenever I call and can provide excellent assistance with repairs, trouble shooting, and part acquisition. D&R Packaging goes out of its way to provide a quality product and to keep it running."

Jedidiah B.

Alex P.

John F.

Jim C.

"EGE Products is an Ag Chemical manufacturing company, and D&R Packaging has been an integral part of our success.

Working with D&R Packaging on our Dual Automated packaging lines is simple and cost effective with their full service program including design, installation, and on-going support.

The customer service at D&R Packaging is top tier. They are available whenever I call and can provide excellent assistance with repairs, trouble shooting, and part acquisition. D&R Packaging goes out of its way to provide a quality product and to keep it running."

Jedidiah B.

Alex P.

John F.

Jim C.

A net weight filler controls the fill by measuring weight, not time or volume. Each jug is isolated on its own scale, verified in position,

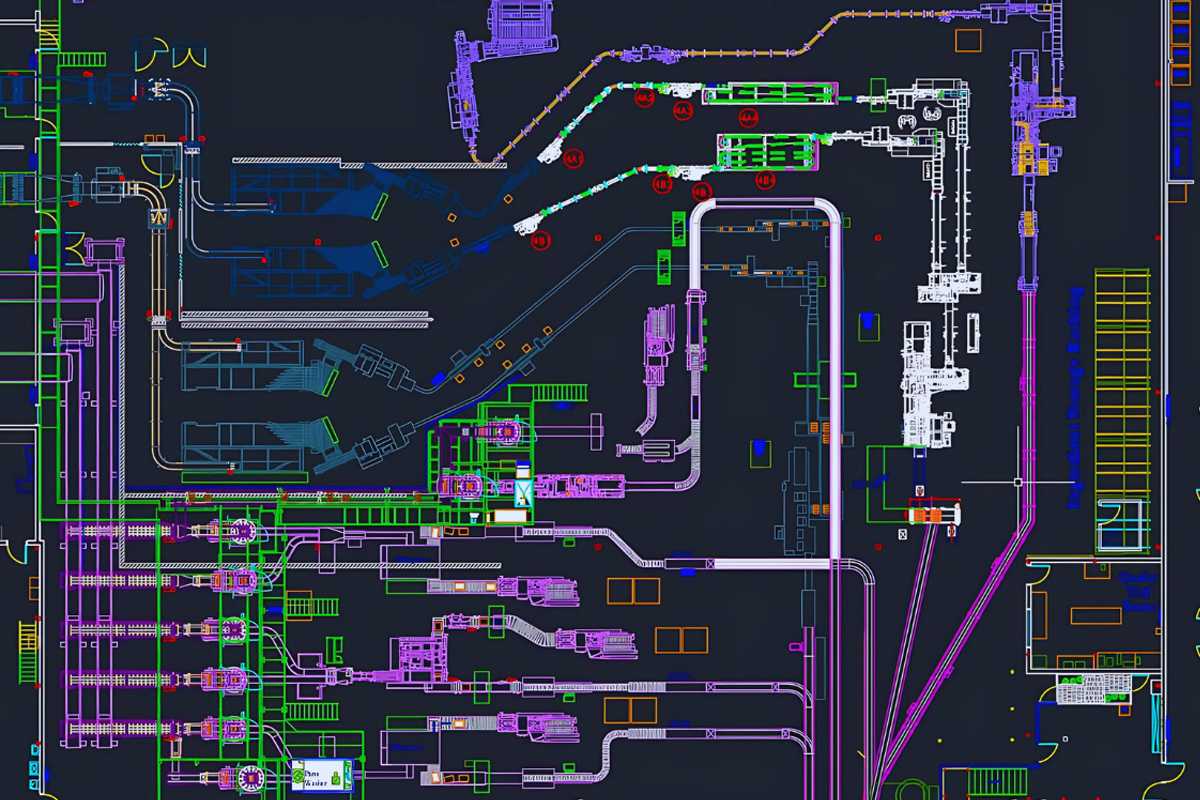

An automated net weight filler only performs as well as the system around it. Seasonal bottle volume, empty container flow, downstream packaging steps, and fluid

F-style jugs are widely used in industries where exact measurements and zero waste are critical. A slight overfill can lead to costly product loss; an