How to Optimize Filling Machine Performance

Are you struggling to maintain efficiency and accuracy in your filling operations? At D&R Packaging, we’ve spent decades perfecting our filling machines to ensure they

Are you struggling to maintain efficiency and accuracy in your filling operations? At D&R Packaging, we’ve spent decades perfecting our filling machines to ensure they

When it comes to ensuring the accuracy and efficiency of your packaging line, selecting the right equipment is crucial. At D&R Packaging, we have spent

Net weight filling technology is transforming the packaging industry by delivering unparalleled precision, ensuring every container is filled to an exact target weight. For industries

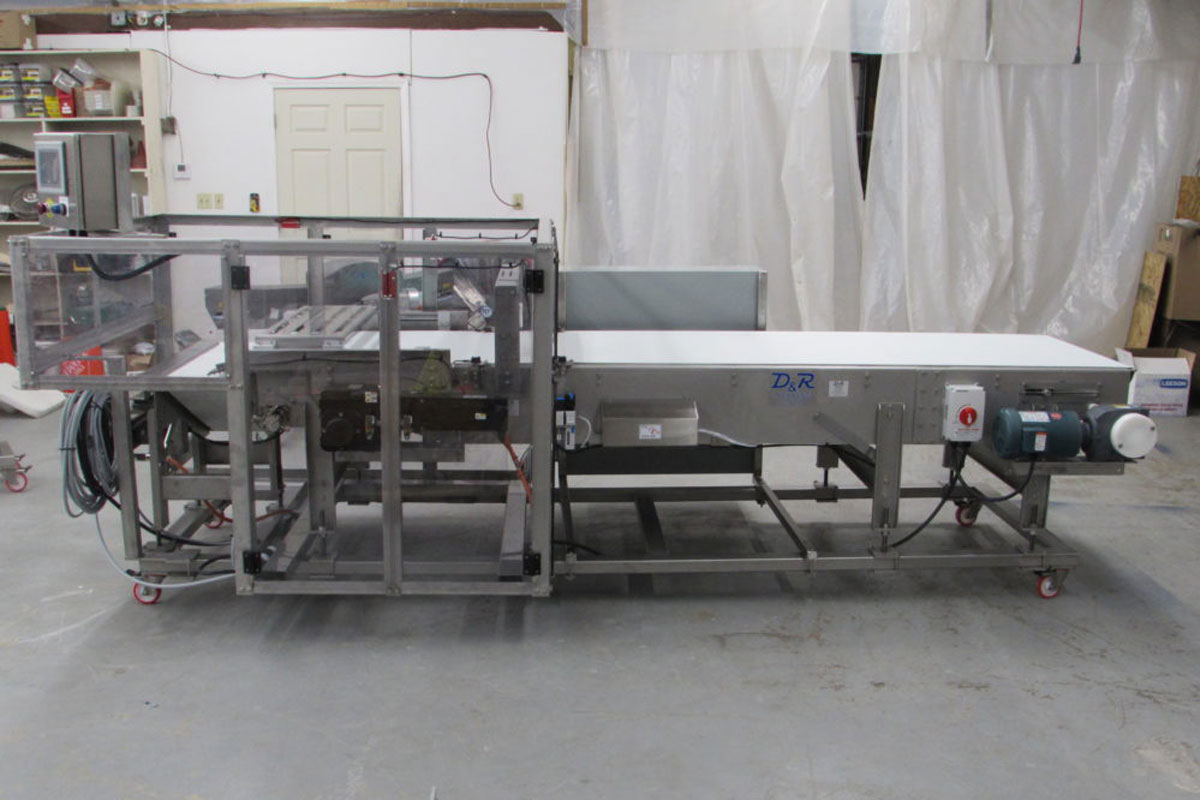

The tape application machine is designed to be at the end of a packaging line for large rolls of film. D&R Packaging can create custom

This 3cnt Packing Line consists of a hand packing station, a labeler, check weigher and metal detector, heat shrink tunnel, and accumulation table. The full

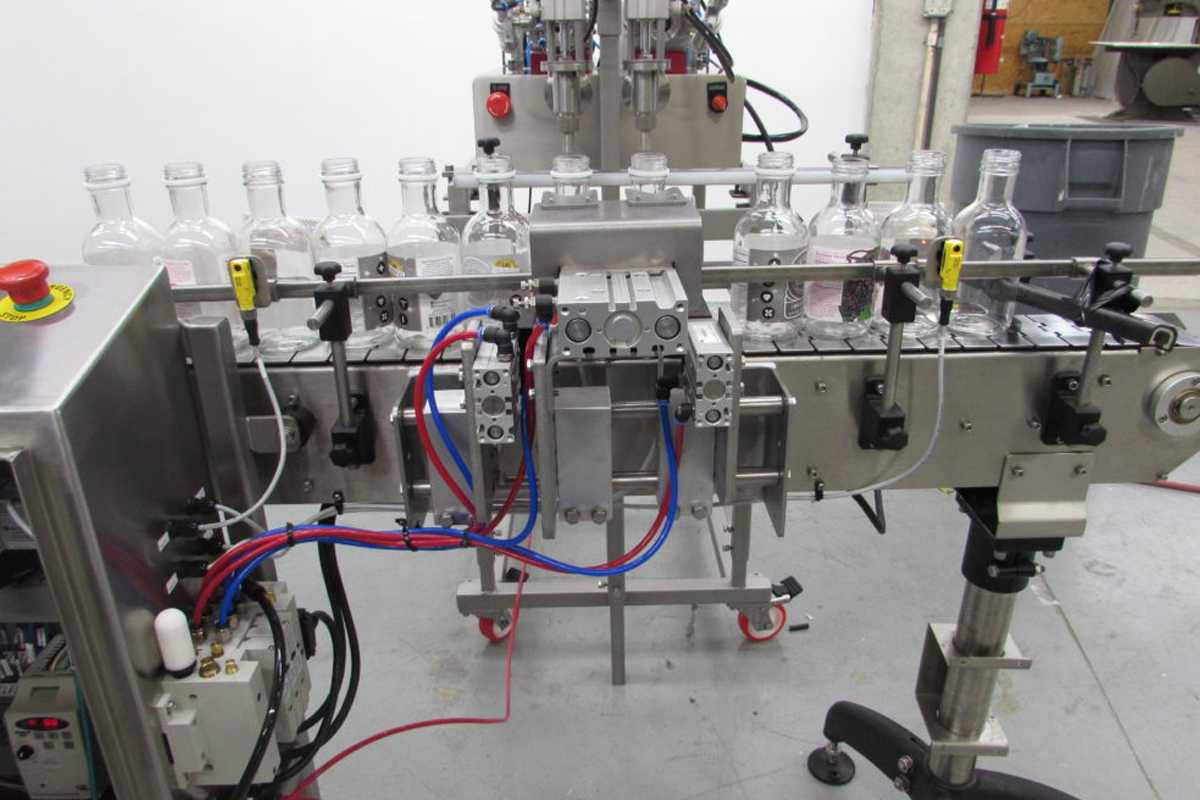

D&R Packaging designed this piston filler for a Kombucha company. It is an integrated product conveyor for automatic filling with PLC controlled product gating system-

This is our high speed check weigher for aerosol cans and various products. Our high speed check weigher can go through over 100 parts per

This custom project is an automatic conveyor labeling system made up of multiple stations. The first station does a 3 panel wrap label on a

Our latest project was for a company that makes and packages candy bars. We designed a retracting nose bar conveyor for a 90 degree transfer

"EGE Products is an Ag Chemical manufacturing company, and D&R Packaging has been an integral part of our success.

Working with D&R Packaging on our Dual Automated packaging lines is simple and cost effective with their full service program including design, installation, and on-going support.

The customer service at D&R Packaging is top tier. They are available whenever I call and can provide excellent assistance with repairs, trouble shooting, and part acquisition. D&R Packaging goes out of its way to provide a quality product and to keep it running."

Jedidiah B.

Alex P.

John F.

Jim C.

"EGE Products is an Ag Chemical manufacturing company, and D&R Packaging has been an integral part of our success.

Working with D&R Packaging on our Dual Automated packaging lines is simple and cost effective with their full service program including design, installation, and on-going support.

The customer service at D&R Packaging is top tier. They are available whenever I call and can provide excellent assistance with repairs, trouble shooting, and part acquisition. D&R Packaging goes out of its way to provide a quality product and to keep it running."

Jedidiah B.

Alex P.

John F.

Jim C.