Pharmaceutical grade, stainless steel construction. This conveying system was designed to recirculate 1 hour’s worth of labeled, temperature sensitive product. Operators hand pack clamshell cases with product, which are then shuttled off to be case packed and refrigerated. Bi-Flow Conveyor Video

Suspended Checkweigh and Retracting Reject Conveyors

Recently completed, these custom conveyor systems were designed to checkweigh and reject 50-100 lb. bags of concrete. The larger are 12′ OAL x 3′ OAW; the smaller is 8′ OAL x 4′ OAW. Scales may be mounted at an incline and still achieve precision checkweighing. As with all D&R designs, these were built with maintenance ease in mind. These stout …

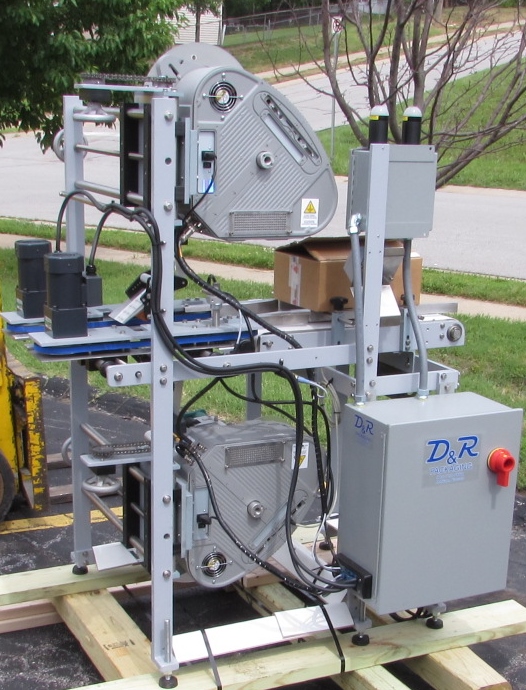

Portable U-base labeling station with print-apply and barcode verification

A compact, portable, low-cost option for labeling and verification of dated or indexed product information. We integrated our customer’s existing tamp-apply labeler and provided the electrical engineering to use an existing Cognex vision sensor for barcode verification, and combined it all into one caster-mounted station ready for use at a moment’s notice wherever it’s needed in the plant. As always, …

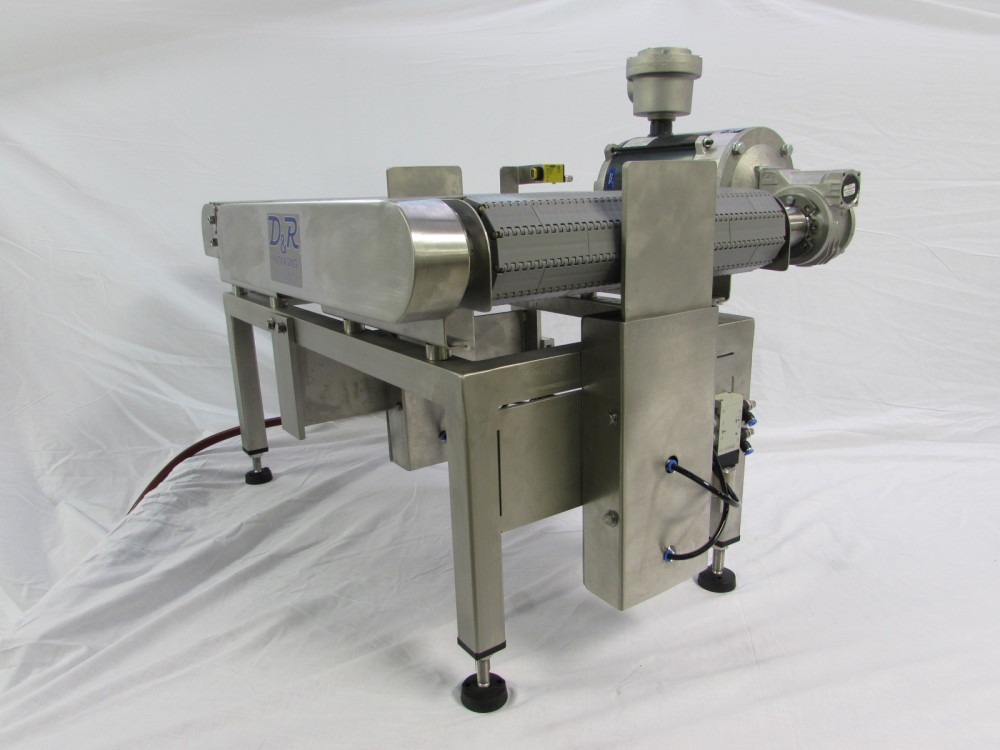

Food-grade sterile wash-down conveyors

Full wash-down, food-grade, stainless steel conveyors with tabletop and mattop chains. Low-priced, and even lower lead times.

Explosion-Proof Scale and Fill Station Conveyors

Stainless steel, sterile wash-down construction for use in hazardous locations. The belt conveyor will mount to a scale platform, and will be a check weigh station before the two small table top chain conveyors, which will be hand pack stations. The pneumatic blade stops are controlled by an explosion-proof foot switch. Shown with custom explosion-proof operator panel.

Dual-Opposing Cornerwrap Print-Apply Labeling System

Dual-Oppposing Cornerwrap Print-Apply Labeling System Video Dual-Opposing, Cornerwrap, Print-Apply Labeling in less than five feet conveyor length. No servo motors, no PLC. When run in tandem with a simple gating system, there are no timing adjustments required for different speeds or product sizes. All heads are right hand, mounted on wheeled bases, and use quick disconnects for complete interchangeability, which …

New Pharma-grade conveyors

We recently shipped these two conveyors: a double-90 degree pharma grade table top chain conveyor and a single-90 portable pharma grade table top chain conveyor. Both conveyors are mounted on offset legs for use in side-transfer applications conveying small glass bottles, and were custom manufactured for easy integration into existing production lines.

Check-weigh scales and conveyors

Some examples of various checkweigh stations built to integrate into any style of production line:

Top – Bottom Labeler with Gang of Conveyors and Hugger Belts

Labels box tops and bottoms simultaneously, and is fully height and width adjustable to accommodate a large variation of product sizes. Designed with easy and intuitive operation, this machine is ready for many years of reliable production. Top-Bottom Labeler Video

Portable Conveyor with Enercon Induction Sealer

Portable, powder coated steel construction, this conveyor is just one example of D&R’s innumerable custom conveyor designs to fit any application. Check out our video slideshow for some more examples of the custom conveyors we have currently operating in plants throughout the country: Custom Conveyors Video Slideshow

- Page 1 of 2

- 1

- 2