When to Use Net Weight Filling in Packaging Lines

Net weight filling in packaging lines is used when yield control, accuracy, and repeatability directly impact production costs and profitability. Manufacturers rely on this method

When it comes to packaging solutions, labeling machinery plays a crucial role in ensuring that products are presented consistently and professionally. At D&R Packaging, we understand the significance of reliable labeling equipment and have been committed to providing top-notch solutions since 1986. In this post, we’ll explore the importance of product handling, the reliability of our labeling heads, the role of customer support, and the benefits of customization and aftermarket support.

Labeling machinery is vital for any business looking to maintain a high standard of product presentation. Accurate and consistent labeling not only enhances the aesthetic appeal of products but also ensures compliance with industry regulations. At D&R Packaging, we prioritize the following key aspects to deliver the best labeling solutions:

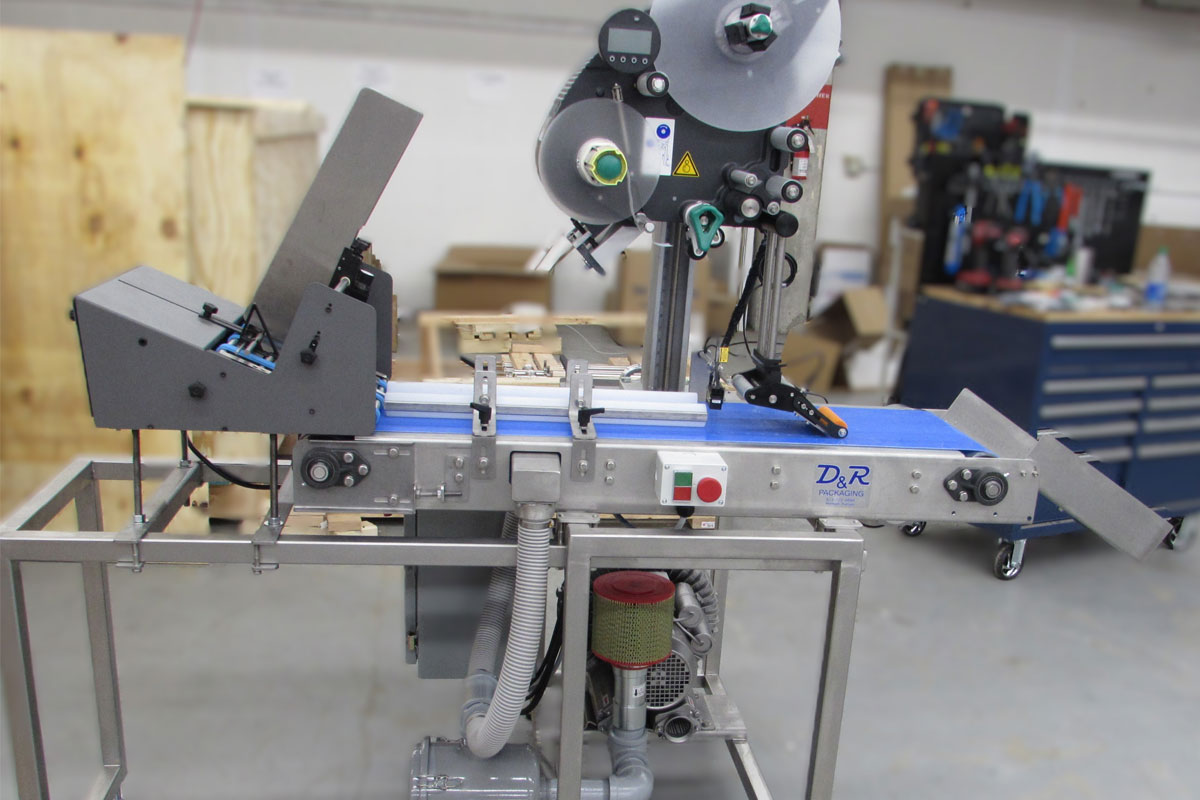

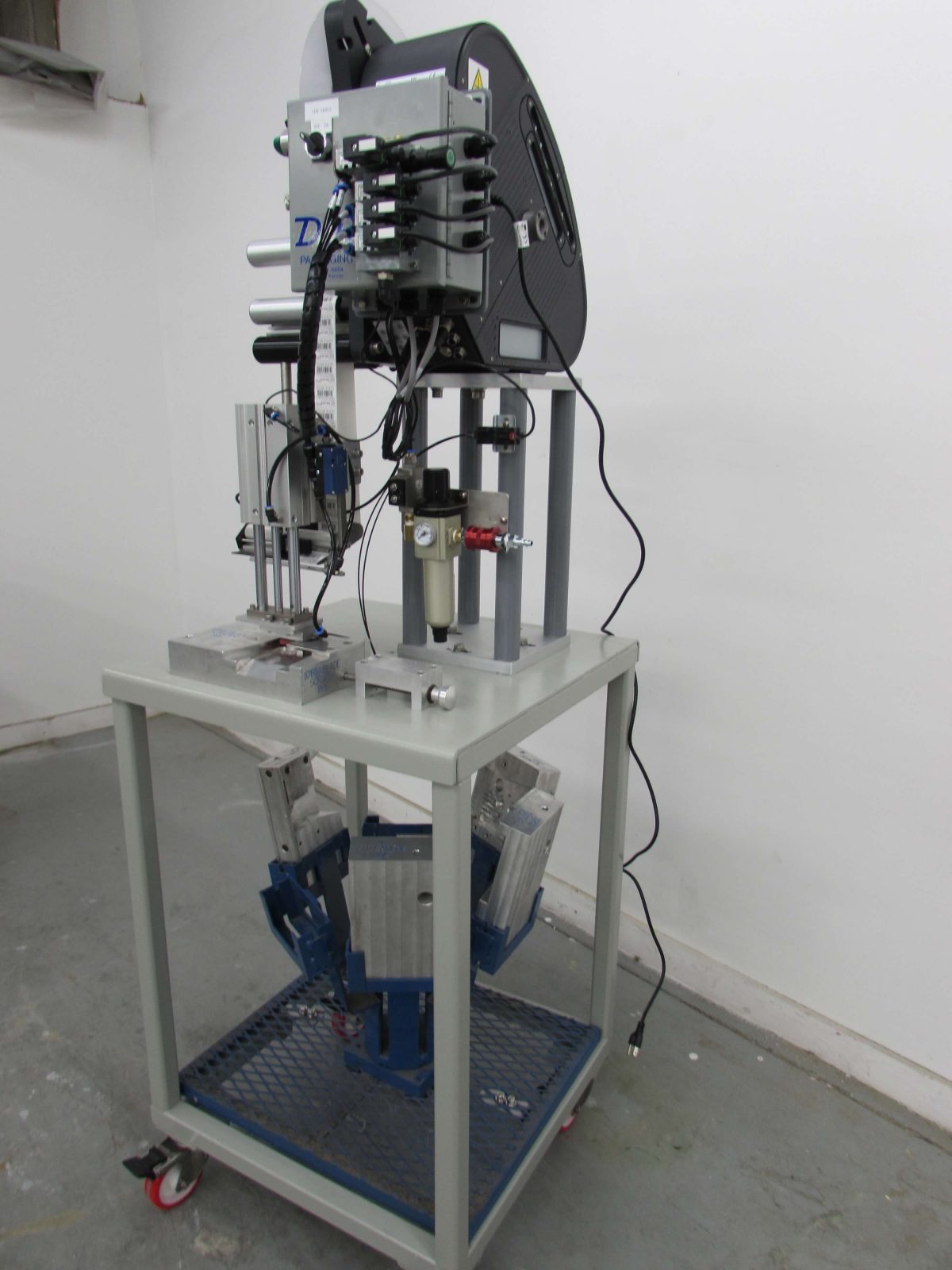

When we take on a labeling project at D&R Packaging, the first aspect we focus on is product handling. How we manage and control the product in front of the labeling head is paramount to achieving flawless label application. We ensure that the product is presented to the peel edge very consistently, time after time. This consistency is the foundation of high-quality labeling.

Supporting our customers is at the heart of what we do. We keep an extensive inventory of spare parts to ensure that our clients’ labeling machinery operates smoothly without prolonged downtimes. Our commitment to customer support extends beyond the initial purchase, as we provide continuous assistance to maintain optimal performance of the labeling systems.

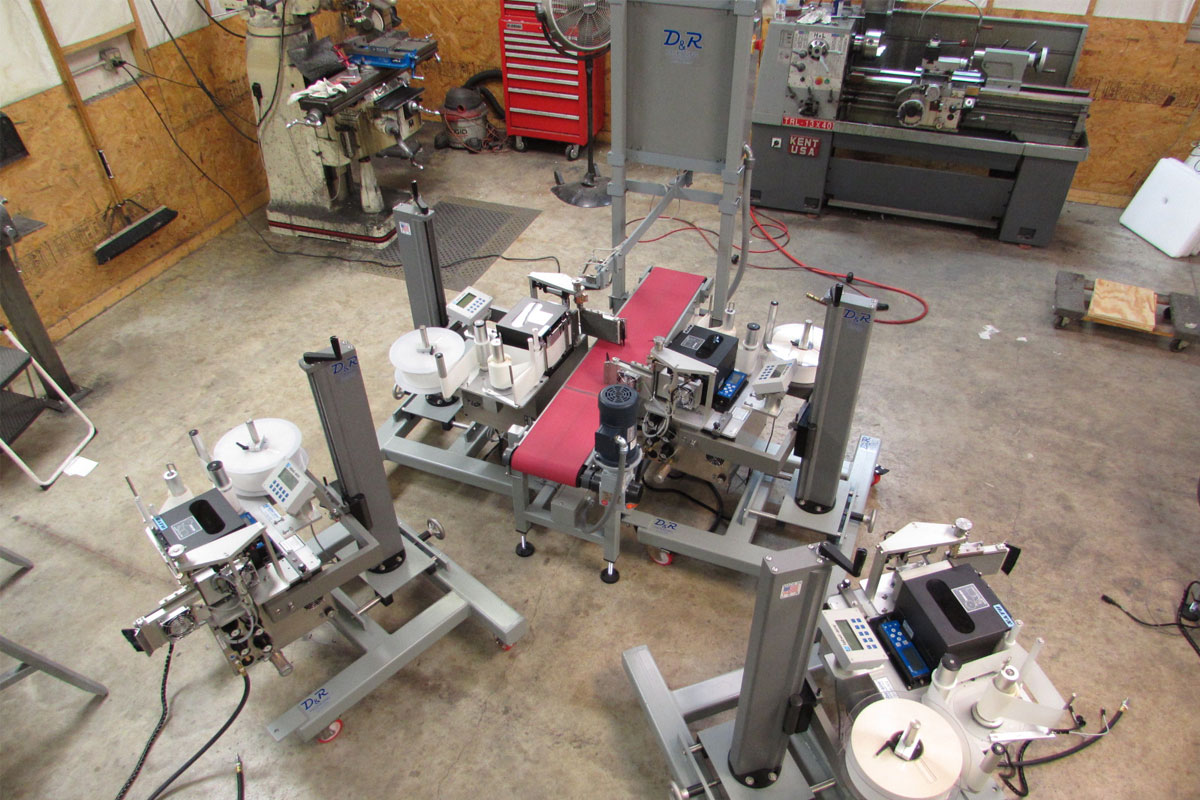

From full turnkey production lines to single pieces of product handling equipment, we provide efficient and cost-effective solutions tailored to your needs. Our equipment is designed for both current production capacity and future growth, ensuring that your investment pays off in the long run.

"EGE Products is an Ag Chemical manufacturing company, and D&R Packaging has been an integral part of our success.

Working with D&R Packaging on our Dual Automated packaging lines is simple and cost effective with their full service program including design, installation, and on-going support.

The customer service at D&R Packaging is top tier. They are available whenever I call and can provide excellent assistance with repairs, trouble shooting, and part acquisition. D&R Packaging goes out of its way to provide a quality product and to keep it running."

Jedidiah B.

Alex P.

John F.

Jim C.

"EGE Products is an Ag Chemical manufacturing company, and D&R Packaging has been an integral part of our success.

Working with D&R Packaging on our Dual Automated packaging lines is simple and cost effective with their full service program including design, installation, and on-going support.

The customer service at D&R Packaging is top tier. They are available whenever I call and can provide excellent assistance with repairs, trouble shooting, and part acquisition. D&R Packaging goes out of its way to provide a quality product and to keep it running."

Jedidiah B.

Alex P.

John F.

Jim C.

Net weight filling in packaging lines is used when yield control, accuracy, and repeatability directly impact production costs and profitability. Manufacturers rely on this method

When a filling line falls behind, the issue is often not the filler. It is inconsistent bottle feeding, slow capping, or finishing steps that force

A net weight filler controls the fill by measuring weight, not time or volume. Each jug is isolated on its own scale, verified in position,