When to Use Net Weight Filling in Packaging Lines

Net weight filling in packaging lines is used when yield control, accuracy, and repeatability directly impact production costs and profitability. Manufacturers rely on this method

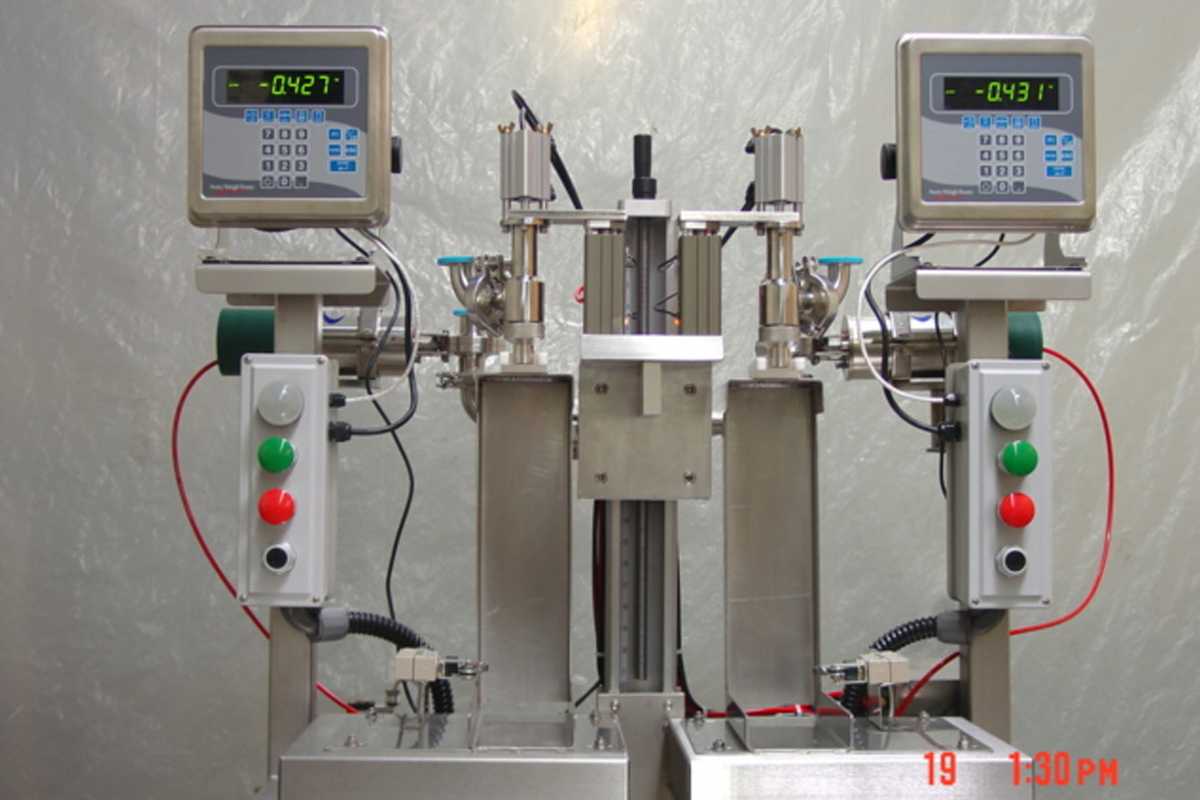

The crux of every packaging operation. D&R possesses the expertise necessary to get your product into its vessel and sealed accordingly. We have developed custom scale-based, piston, auger, and positive displacement filling solutions for a variety of food and pharmaceutical applications.

We’ve got you covered on capping and sealing too, whether it be a custom solution or integration of an existing machine. We have many systems for cap feeding, capping, sealing, and tamper sealing currently in operation in the plants of some of the country’s most trusted manufacturers.

As in all areas, we maintain good relations with the industry’s leading packaging machinery manufacturers, and are happy to act as advocates on our customer’s behalf to ensure you get the best machine for your application.

"EGE Products is an Ag Chemical manufacturing company, and D&R Packaging has been an integral part of our success.

Working with D&R Packaging on our Dual Automated packaging lines is simple and cost effective with their full service program including design, installation, and on-going support.

The customer service at D&R Packaging is top tier. They are available whenever I call and can provide excellent assistance with repairs, trouble shooting, and part acquisition. D&R Packaging goes out of its way to provide a quality product and to keep it running."

Jedidiah B.

Alex P.

John F.

Jim C.

"EGE Products is an Ag Chemical manufacturing company, and D&R Packaging has been an integral part of our success.

Working with D&R Packaging on our Dual Automated packaging lines is simple and cost effective with their full service program including design, installation, and on-going support.

The customer service at D&R Packaging is top tier. They are available whenever I call and can provide excellent assistance with repairs, trouble shooting, and part acquisition. D&R Packaging goes out of its way to provide a quality product and to keep it running."

Jedidiah B.

Alex P.

John F.

Jim C.

Net weight filling in packaging lines is used when yield control, accuracy, and repeatability directly impact production costs and profitability. Manufacturers rely on this method

When a filling line falls behind, the issue is often not the filler. It is inconsistent bottle feeding, slow capping, or finishing steps that force

A net weight filler controls the fill by measuring weight, not time or volume. Each jug is isolated on its own scale, verified in position,