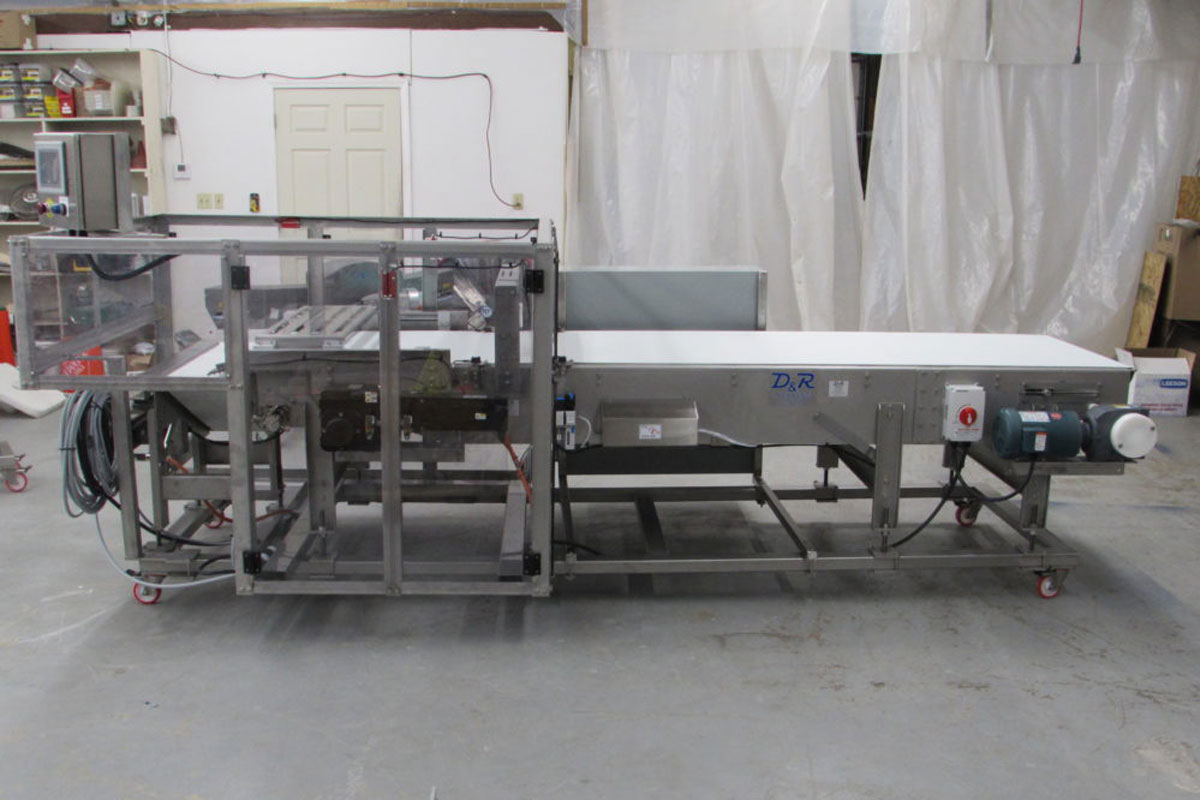

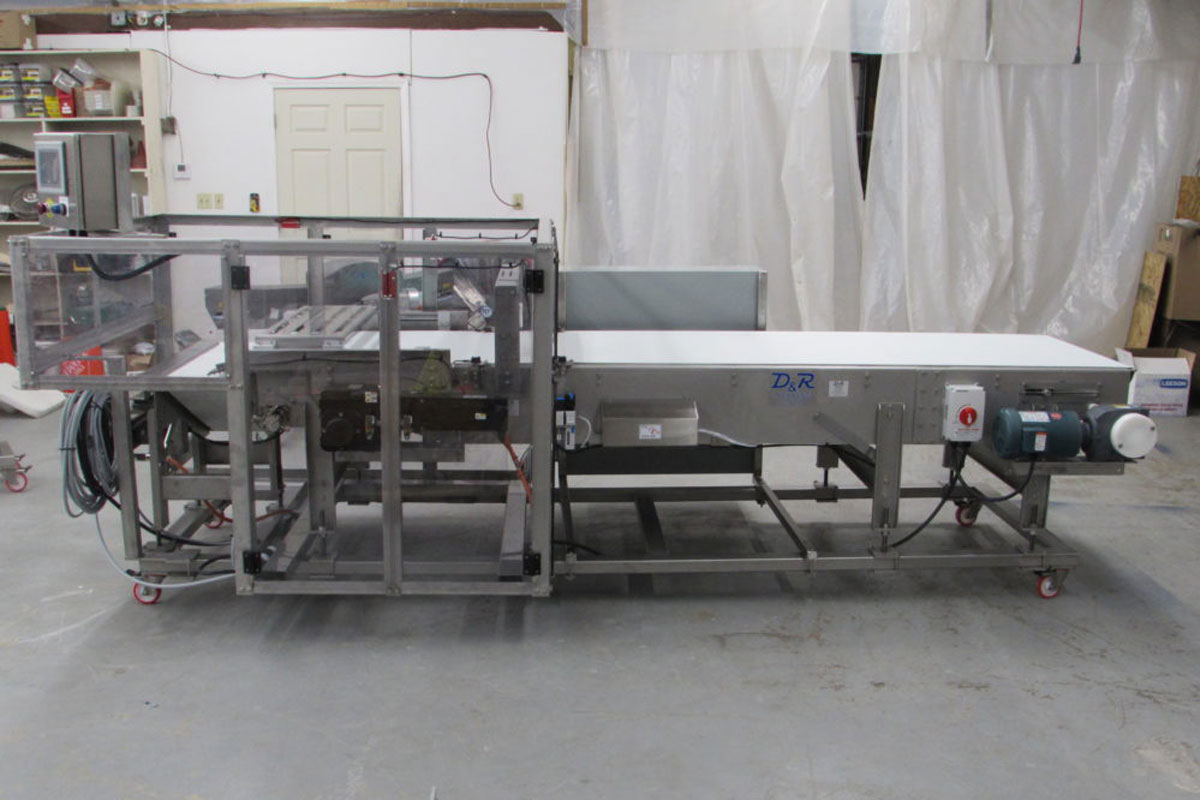

Candy Bar Transfer Conveyor (Retracting Nose Bar Conveyor)

Our latest project was for a company that makes and packages candy bars. We designed a retracting nose bar conveyor for a 90 degree transfer

Our latest project was for a company that makes and packages candy bars. We designed a retracting nose bar conveyor for a 90 degree transfer

Our latest checkweighers – the Intermittent Motion Case Checkweigher and the In Motion Poly Bag Checkweigher. These two different Checkweighers each check the weight of

This is one of our latest Bottle Labeling Lines, featuring four different conveyors (accumulation table, labeling, bi-flow, and lower conveyor at the packing station). This

This versatile labeling machine uses wipe-on label applicators to adhere labels to both front and back for an array of products. The user can adjust

We recently designed a custom bottle filling line that can fill ten to fourteen 2.5 gallon jugs per-minute, depending on the product. It features a

Pharmaceutical grade, stainless steel construction. This conveying system was designed to recirculate 1 hour’s worth of labeled, temperature sensitive product. Operators hand pack clamshell cases

Recently completed, these custom conveyor systems were designed to checkweigh and reject 50-100 lb. bags of concrete. The larger are 12′ OAL x 3′ OAW;

A compact, portable, low-cost option for labeling and verification of dated or indexed product information. We integrated our customer’s existing tamp-apply labeler and provided the

Full wash-down, food-grade, stainless steel conveyors with tabletop and mattop chains. Low-priced, and even lower lead times.

Stainless steel, sterile wash-down construction for use in hazardous locations. The belt conveyor will mount to a scale platform, and will be a check weigh