The tape application machine is designed to be at the end of a packaging line for large rolls of film. D&R Packaging can create custom machinery to fit the needs of your industry and product. This specific machine was designed for plastic wrap (also known as cling wrap). This machine applies a strip of tape to a signal the end …

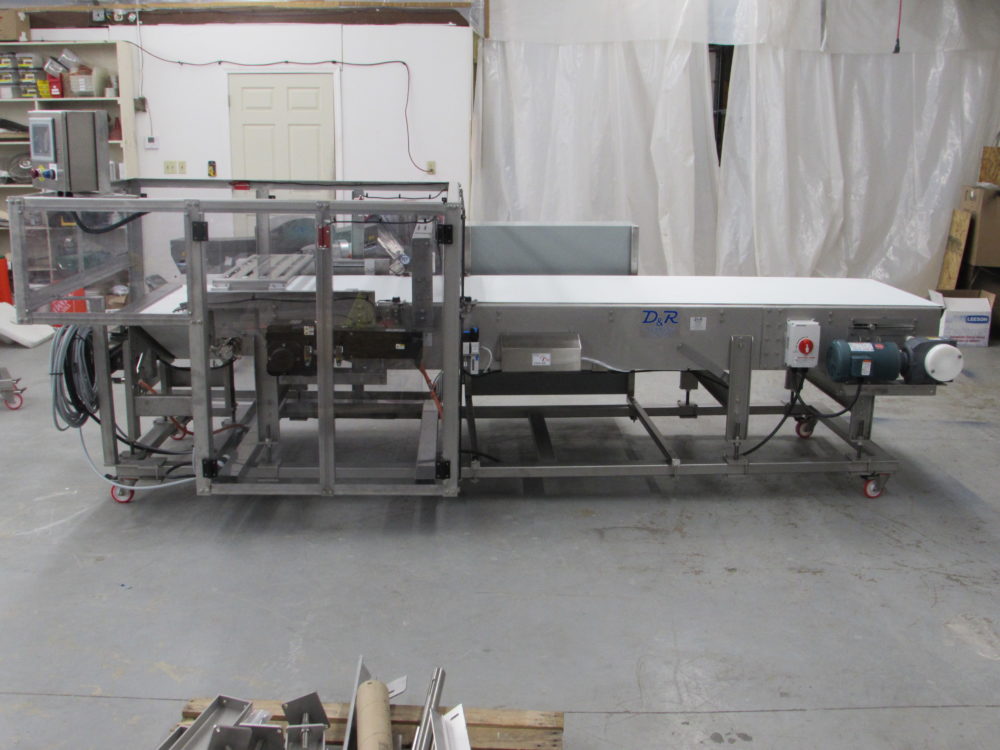

3cnt Packing Line for Bakery Products

This 3cnt Packing Line consists of a hand packing station, a labeler, check weigher and metal detector, heat shrink tunnel, and accumulation table. The full line is capable of doing 25-30 parts per minute. The product line begins at the hand packing station where the baked product is put into a clam shell container. The containers then go through a …

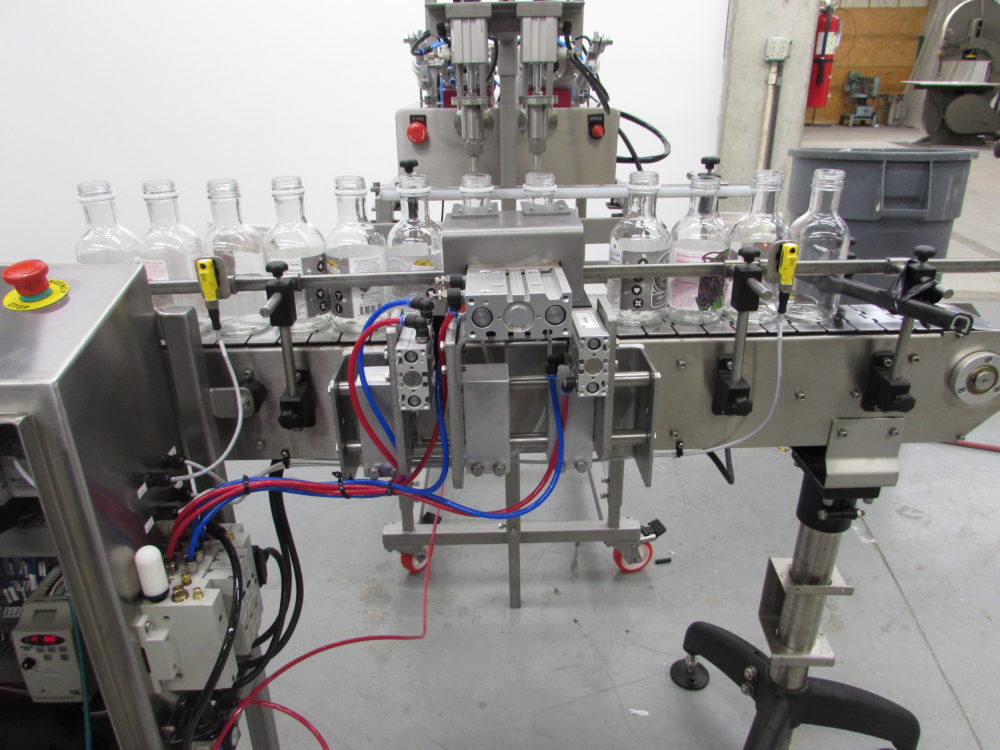

Kombucha Bottle Compact Piston Filler – Custom Machinery

D&R Packaging designed this piston filler for a Kombucha company. It is an integrated product conveyor for automatic filling with PLC controlled product gating system- including bottle neck locators, no bottle no-fill detection, and downstream backup interlocking. This type of project can be customized with various additions or modifications based on your company’s and/or product’s needs. For instance; this system …

High Speed Check Weigher

This is our high speed check weigher for aerosol cans and various products. Our high speed check weigher can go through over 100 parts per minute. Talk about fast- checking one hundred plus products in a minute or less! This checkweigher is using a Wipotec loadcell and Rice Lake scaling controls. Scale programming provides real time data back to process …

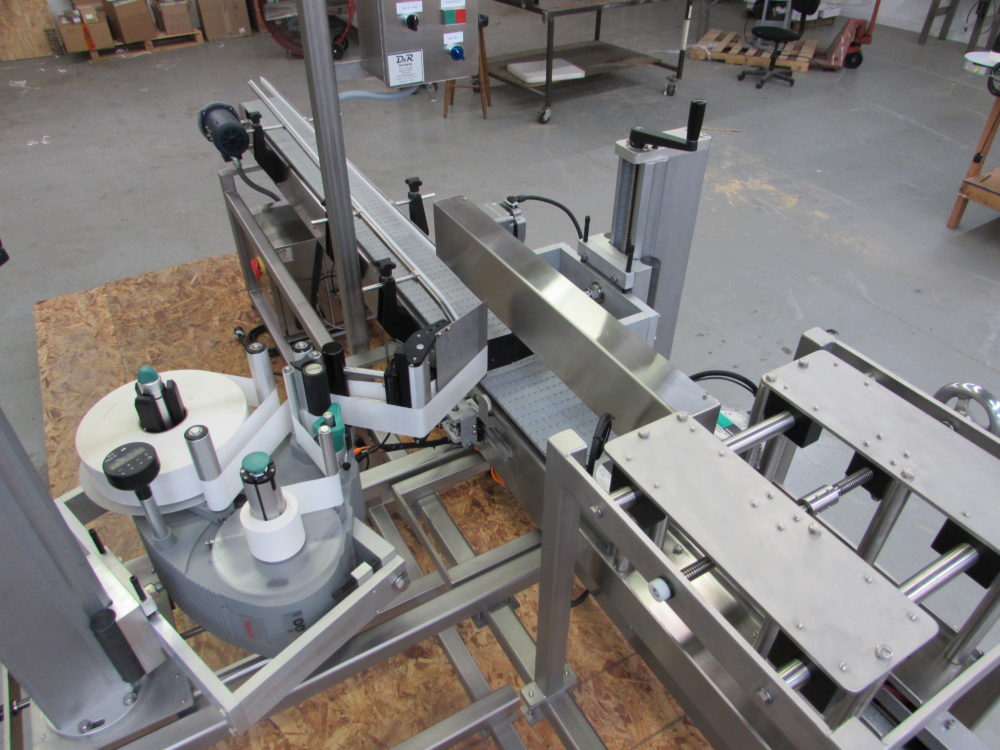

Two Station Labeler for Square and Round Bottles

This custom project is an automatic conveyor labeling system made up of multiple stations. The first station does a 3 panel wrap label on a square or rectangular bottle. The second station does a round bottle wrap label. The system has a 12ft long product conveyor, 2 Novex SLX206 label applicators,saloon door style 3 panel applicator with vacuum, a tilt …

Candy Bar Transfer Conveyor (Retracting Nose Bar Conveyor)

Our latest project was for a company that makes and packages candy bars. We designed a retracting nose bar conveyor for a 90 degree transfer of chocolate candy bars. This system is constructed of stainless steel and can be fully washed down, it is also caster mounted for portability. This conveyor features 34 inch wide food grade belting, automatic belt …

Intermittent Motion Case Checkweigher and an In Motion Poly Bag Checkweigher

Our latest checkweighers – the Intermittent Motion Case Checkweigher and the In Motion Poly Bag Checkweigher. These two different Checkweighers each check the weight of an object to ensure accuracy and eliminate product waste. Each has an Annunciation light that illuminate to indicate if the object is within the target weight range. If not the Intermittent Motion Case Checkweigher conveyor …

Bottle Labeling Line

This is one of our latest Bottle Labeling Lines, featuring four different conveyors (accumulation table, labeling, bi-flow, and lower conveyor at the packing station). This line has duel thermal transfer overprinters for printing the lot/date information and 2D barcode generation on each label. With a barcode verification sensor and print inspection camera this line ensures each and every label is …

Front and Back Labeling Machine

This versatile labeling machine uses wipe-on label applicators to adhere labels to both front and back for an array of products. The user can adjust the speed of application/ speed of the conveyor, the labeling head height, and the rail width giving you tons of options for every individual product. Locator brushes can also be adjusted for the perfect alignment, …

Filling Line with Two Headed Net-Weight Filler

We recently designed a custom bottle filling line that can fill ten to fourteen 2.5 gallon jugs per-minute, depending on the product. It features a custom built stainless steel conveyor, Gating system, and Two-Headed Net Weight fillers. The system also includes: Wipe on labeler, Allen Bradley PLC and Touch Screen Controls, Two-Headed Net weight filler with HMI screen, neck locators, …

- Page 1 of 2

- 1

- 2